Our Process

From project framework to detailed fab-work, we take a thorough approach to getting the job done.

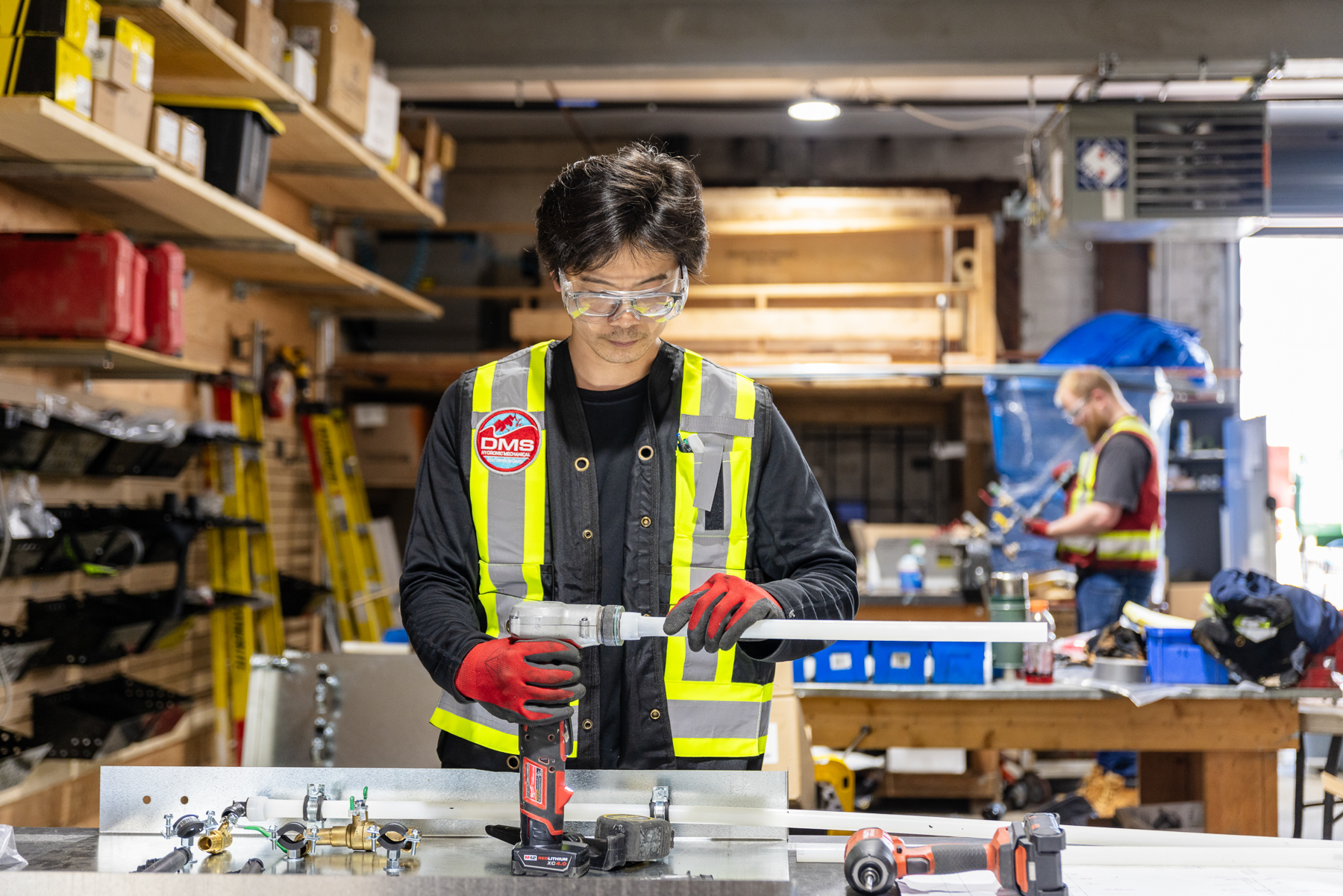

Fabrication Shop

New and improved in-house fabrication capabilities.

We’ve reinvested in ourselves and, to show for it, we’re proud to unveil a brand new, top-of-the-line fabrication shop.

What does our leveling-up mean for you? Well, it means that we’re able to continue doing what we do best, plus, so much more.

- Enhanced pipe threading along with cut, groove, and drilling of stainless steel and black iron.

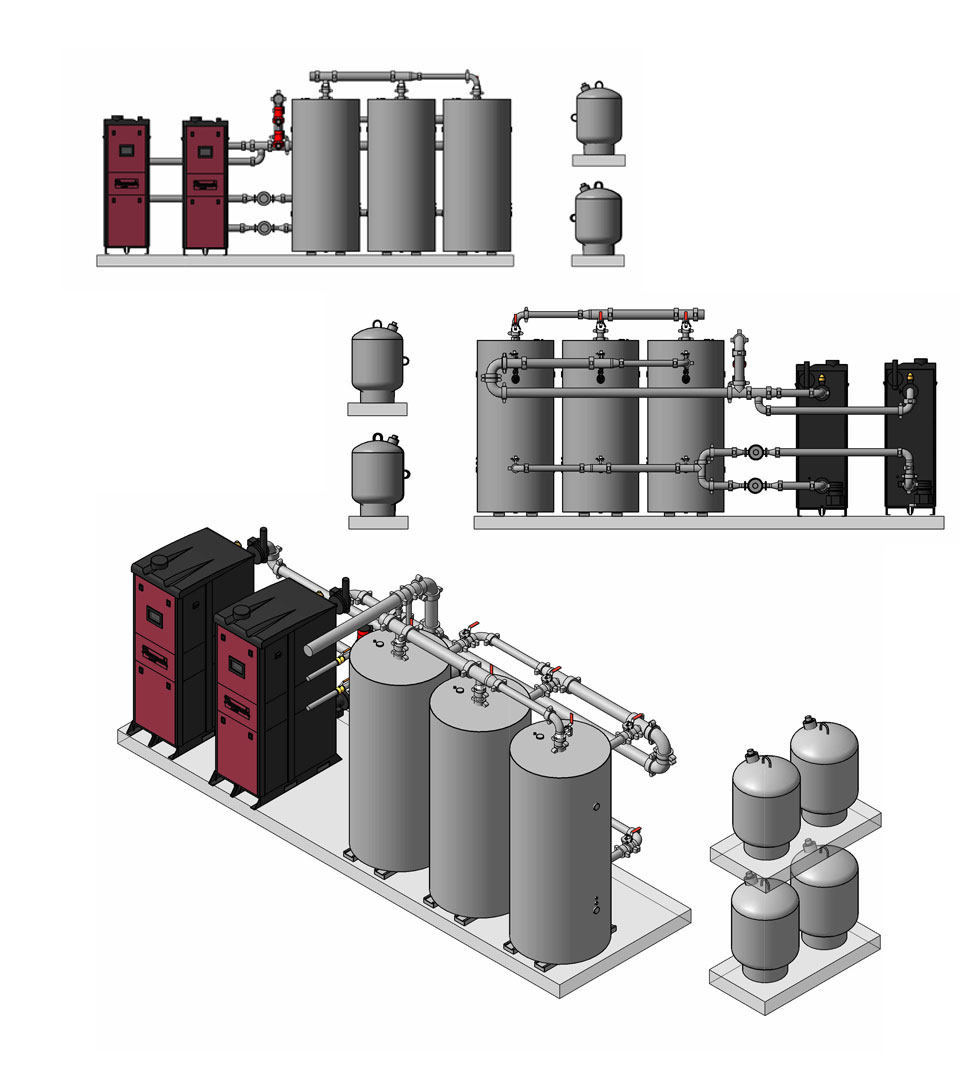

- Build manifolds, PRV Stations, recirculation stations, and heat exchangers.

- Repeatable and reliable fabrication and packaging of components in a controlled environment.

- Better utilization of material inputs and a reduction of wasted materials on site.

- Technologies to improve build complexity, while speeding up fabrication efficiency.

No. 01

Define.

We’re a company that’s thrived from strong, long-standing relationships. And, to build a good relationship, you need a strong foundation. For us, we see a clearly defined set of expectations as that foundational element that then allows us to work toward meeting (and exceeding) them.

No. 02

Design.

We’ve seen a thing or two in a couple of decades of business. This perspective, along with our growing mechanical expertise, enables us to work within many building configurations. And, with modern technologies like BIM and CAD at our fingertips, we’re able to design solutions that avoid inefficiencies during installation.

No. 03

Refine.

Continuous improvement is a philosophy that we can get behind. Not only is this a mindset that we take during projects to make sure we’re delivering above and beyond, but we’re also always looking at new ways, products, techniques, and systems to get us there.

No. 04

Execute.

This is where the grind begins (but not in a bad way). Our highly-skilled technicians and fabricators work in a state-of-the-art controlled shop environment that confirms quality, while our installation teams reach new heights of system implementation.

Featured Projects

More than 25 years of comprehensive mechanical contracting solutions in Vancouver.

The Towers at Latimer Heights

Latimer Heights is the largest master-planned community in the history of Langley. For Latimer Heights, we have been engaged to provide complete mechanical system solutions. This includes plumbing, HVAC, gas, sprinklers, refrigeration, balancing, and commissioning.

Tailor

Tailor by Marcon is a sleek, 27-storey residential tower consisting of 165 condominium units and 5 townhomes. DMS was contracted to perform comprehensive mechanical construction and installation throughout the project.

Savoy

Providing full mechanical scope on this sleek and modern low rise, DMS installed a highly efficient HVAC-R system to deliver maximum comfort for its residents.

HUB Place

This modern rental tower by Jameson Development is situated in the HUB of East Vancouver, and features a highly sustainable heating and cooling system.

Sydney

DMS provided full mechanical scope on this elegant tower rising 25 storeys above the growing neighbourhood of Burquitlam.

Maywood on the Park

Rising 32 storeys above its namesake, Maywood on the Park features precision climate control from a four-pipe fan coil system, and takes design inspiration from the green space neighbouring it.

The Grande

Nestled into the heart of Port Moody, The Grande by Onni features two 26 storey luxury towers, supplied with an equally luxurious two pipe heating and cooling system.

1335 Howe

1335 Howe is a modern and sophisticated 40-storey residential tower located in the incredible Beach District. DMS was contracted to install a 4-pipe fan coil system supplied by 14 modular air source chillers to give year-round climate comfort.

River District

The River District is a 130-acre, master-planned waterfront community located in South Vancouver. DMS was contracted to perform full mechanical work across five projects, One Town Centre, Quartet, Avalon 2, Avalon 3, and MODE.

The Amazing Brentwood 3

The Amazing Brentwood 3 rises 55 storeys above one of the busiest urban retail communities in Metro Vancouver, and features a dual mechanical room setup to provide maximum operational efficiency.

Lougheed Heights

DMS completed the full mechanical scope on this large 849 unit project, developed by Bosa Properties. Modern amenities supplement the luxurious lifestyle of this prime location.

1770 Pendrell

1770 Pendrell by Westbank is a 21 floor, 173 unit, modernist icon just steps from English Bay. DMS Mechanical was contracted to install a full mechanical system including an energy transfer station for use by future buildings.